Inflaming Retarding and Antistatic ABS Vacuum Forming Enclosures

Inflaming Retarding and Antistatic ABS Vacuum Forming Enclosures

Details

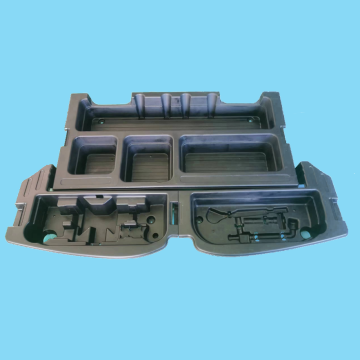

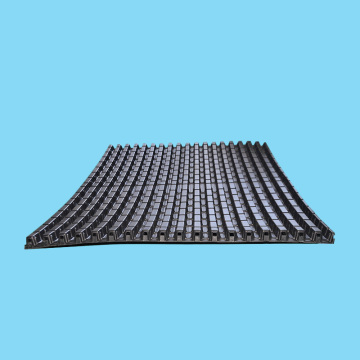

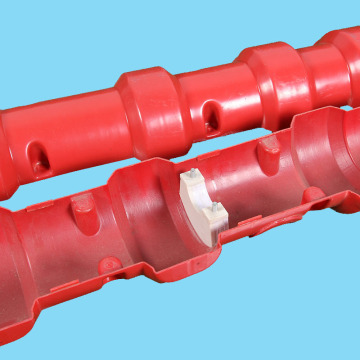

Inflame-Retarding and Antistatic ABS Vacuum Forming Enclosures: Protect your sensitive electronics with our customized ABS enclosures. Reliable flame retardant and antistatic properties ensure safety and quality. Perfect for various industries. Contact us now for tailored solutions.

Acrylonitrile butadiene styrene (ABS) is the most commonly used plastic for vacuum forming. ABS is a hard plastic with a rubber content that makes it resistant to weather and impact. It has a shrinkage rate of 0.3-0.8%.

ABS is often formulated to meet UL flammability standards. It is used to make: Electrical enclosures, Luggage, Sanitary parts, Vehicle parts.

Other materials that can be vacuum formed include:

Polycarbonate, which is strong and transparent

Vacuum forming has the following advantages:

Each piece is relatively fast to produce

Low manufacturing costs

Vacuum forming also has the following disadvantages:

Only one part or product can be made at a time

There may be additional costs or resources needed to finish components

Vacuum forming sheet thickness can range from 0.008 to 0.8 inch (0.2 to 20mm)

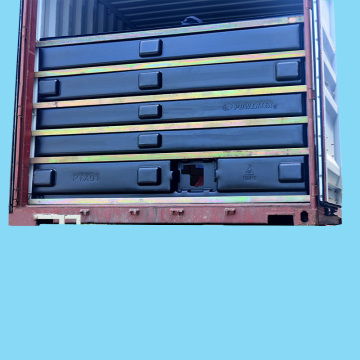

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686

Details

Inflame-Retarding and Antistatic ABS Vacuum Forming Enclosures: Protect your sensitive electronics with our customized ABS enclosures. Reliable flame retardant and antistatic properties ensure safety and quality. Perfect for various industries. Contact us now for tailored solutions.

Acrylonitrile butadiene styrene (ABS) is the most commonly used plastic for vacuum forming. ABS is a hard plastic with a rubber content that makes it resistant to weather and impact. It has a shrinkage rate of 0.3-0.8%.

ABS is often formulated to meet UL flammability standards. It is used to make: Electrical enclosures, Luggage, Sanitary parts, Vehicle parts.

Other materials that can be vacuum formed include:

Polycarbonate, which is strong and transparent

Vacuum forming has the following advantages:

Each piece is relatively fast to produce

Low manufacturing costs

Vacuum forming also has the following disadvantages:

Only one part or product can be made at a time

There may be additional costs or resources needed to finish components

Vacuum forming sheet thickness can range from 0.008 to 0.8 inch (0.2 to 20mm)

Pinghu Yangzhiguang Packaging Products Co.,Ltd. a professional vacuum forming plastic products manufacturer with more than 20 years of production experience. We specialize in producing and customizing a variety of blister packs, plastic trays, plastic boxes, etc... for national and overseas customers. Please contact us for a free quote on your custom design. For more information, call -+8618821226686